- Cold Roll Forming Machines

- Slitting Machine

- High Speed Thin Board Slitting Machine

- Thick Board Slitting Machine

- Simple Slitting Machine

- Cut-To-Length Machine

- High Speed Sheet Cut-To-Length Machine

- Thick Board Cut-To-Length Machine

- Slitter/Cut-To-Length Combination Machine Line

- Pipe Making Machines

- Precision High Frequency Welding Steel Tube Mills

- Precision High Frequency Welded Tube Making Machines

- Stainless Steel Pipe Making Machine

- Vertical/Horizontal High Speed Cold Cutting Saws

- Elevator Guide Rail Producing Line

- Elevator Hollow Guide Rail Producing Line

- Elevator Closed Hollow Guide Rail Producing Line

- CNC Hydraulic Press Brake

- Hydraulic Guillotine Shearing Machine

High Speed Thin Board Slitting Machine

Description

High-speed thin board slitting line is mainly made up of uncoiler, feeder, slitter and recoiler. This high speed metal sheet slitting machine is suitable for cutting or shearing carbon steel, stainless steel, pre-painted steel, galvanized steel, color steel, aluminum and other metal sheets with thickness range from 0.2 mm to 2.0mm.

Features

1. Slitting speed reaches up to 80m/min, and you can adjust any speed as you like within 80m/min.

2. Different profile can be manufactured according to customers’ requirement.

3. Different profile has different thickness range, but all thickness range should be within 0.2 to 2.0mm.

4. It also features high slitting precision, and the slitting width error range is no more than 0.03mm.

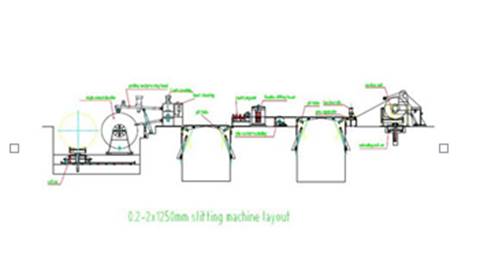

Flow chart of high speed metal sheet slitting machine

Hydraulic coil car→single mandrel de-coiler→head-guiding head shovel and 2 rolls feeding→sheet head shearing machine→Pit(1)→deviation rectifying(sheet guiding)→slitting→side scrap recoiling→pit(2)→pre-separator and damping ,tensioning machine→coil recoiler→unloading coil car→hydraulic control→electrical control

Parameter of metal sheet slitting machine

Materials using this slitting machine

| Raw material | Steel coil material, common carbon steel, galvanized steel or pre-painted steel |

| Coil thickness | 0.2mm to 2.0mm (Note: Different profile can be manufactured according to customers’ requirements. Different profile has different thickness range, but all thickness range should be within 0.2~2.0mm.) |

| Coil diameter | ≤ 2100mm |

| Coil width | 300 to 1250 (mm) |

| Coil inner diameter | ф508mm, ф610mm |

| Coil weight | ≤ 15T |

Round blade slitting of high speed metal sheet slitting machine

| Specification of slitting shaft | ф205mm × 1250mm |

| Material of blades shafts | 40Cr hardened chrome and polishing |

| Material of blades | 6Crw2Si, hardened chrome HRC60-62degrees |

| Slitting motor power | DC55KW motor with joint coupling plus speed reducer |

| Slitting speed | ≤ 80m/min (You can adjust any speed as you like within 80m/min) |

| Slitting width accuracy | ± 0.03mm |

Damping and pre-separator (tension rolls) of metal sheet slitting machine

| Recoiling specification | ф508mm × 1250mm |

| Separator discs | ф200mm × 3mm, 65Mn q |

| Coil pushing arm power | ф80mm × 1400mm |

| Power of recoiling | 75KW DC motor |

| Motor control | Euroasia control 590 |

| Recoiling speed | 0 to 80m/min adjustable |

Hydraulic control of high speed metal sheet slitting machine

| Hydraulic station | 1 set |

| Pressure | 16Mpa |

| Power | 7.5kw-4 |

Electrical control of high speed metal sheet slitting machine

| Electrical cabinet | 1 set |

| Operation cabinet | 2 sets |

| Control system | Mitsubishi PLC |

SUZHOU MANFENGXIANG TECHNOLOGY CO.,LTD. is dedicated in designing and supplying manufacturing different steel cutting, bending and forming equipments, including tube mills, roll forming machines, etc. Apart from tube making machine and steel roll forming machine, we devoted ourselves to the research & development of various kinds of other products related to steel structure, such as hydraulic press brake machine, roll former, shearing machine, metal sheet slitting machine, cutting machine, production lines of guardrail sheet for expressway, shutter doors, and garages doors, etc. Our products are well received by customers from North America, South America, Europe, Middle East, Southeast Asia, Russia, Australia and other regions. Welcome to visit our company and discuss your needs face to face.

- Thick Board Slitting MachineThick board slitting machine is a member of slitting line used for cutting metal material into different width. Thick steel coil slitting line is mainly composed of uncoiler, feeder, slitter and recoiler, and it is mainly applied for cutting different types of thick steel materials, such as steel coil, carbon steel, galvanized steel and pre-painted steel...